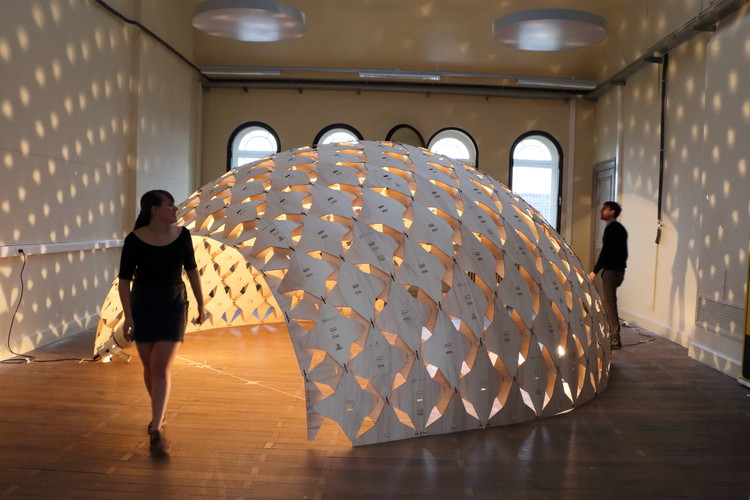

"Exoskeleton" is a pavilion that shows how Computer Aided Manufacturing can create rapid prototypes. This manufacturing process allows for real-scale construction and experimentation with limited resources.

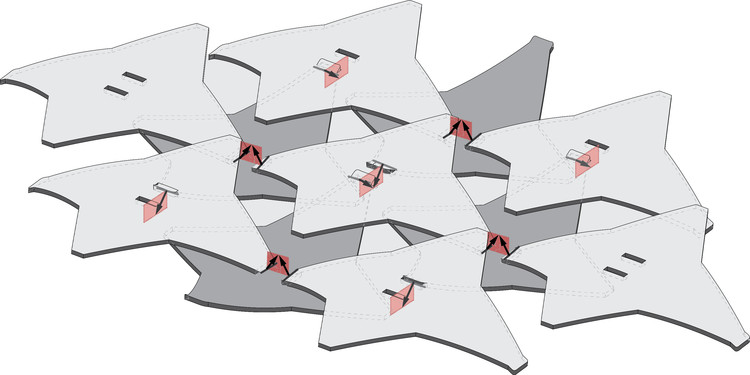

In this project, a system of modules, designed with different dimensions, is put together with simple joints without nails or screws. This allows for different surfaces to be formed and for the pieces to be rotated and assembled at various angles and heights.

From the architects. Our master dissertation investigated a ‘bottom-up’ approach to structural design by means of prototyping, a subcategory of digital fabrication. The design of a small pavilion, the Exoskeleton, served as a test case.

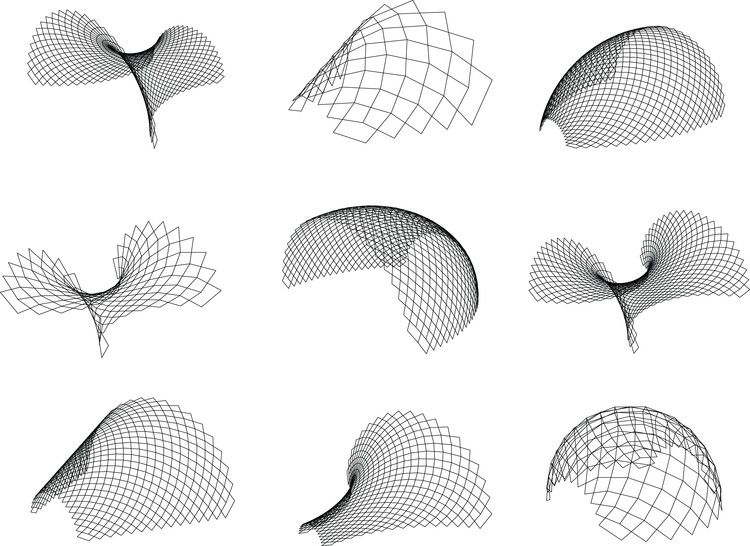

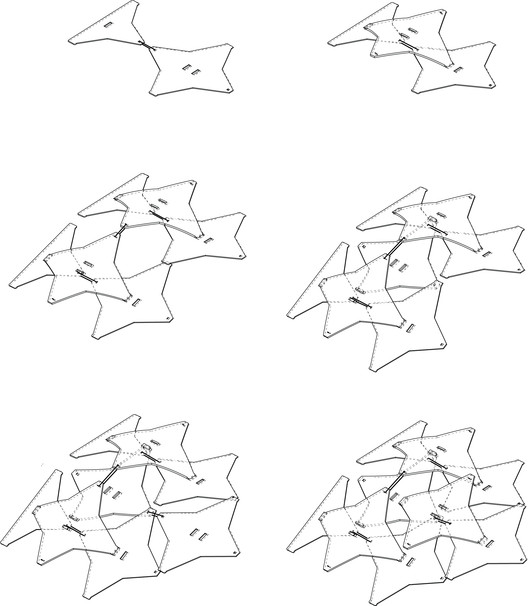

This ‘bottom-up’ approach allowed for working in an empirical way; new ideas were validated through immediate physical testing of their constructional behavior. In this way the total design of the pavilion did not arise from an overarching 3D-model, deriving components from the overall shape, but instead from an iterative design process, whereby first the components and only then the overall shape were determined through prototyping.

Applying this bottom-up approach to structural design enabled a detachment from well-defined structural typologies. Since knowledge was gradually built up during the design process, this approach enabled to investigate innovative structural principles or a new application of a certain material. A hands-on understanding of the structural behaviour of a certain construction was developed during the design process.

Computer Aided Manufacturing was instrumental to this approach, as it allows for rapid fabrication of numerous prototypes. This rapid prototyping method enabled us to quickly test and learn. Making the design process affordable, was only possible if the materials used for the physical models were cheap and the fabrication techniques were fast. Hence limitations concerning budget and availability of fabrication techniques were taken into account from the start of the design process.

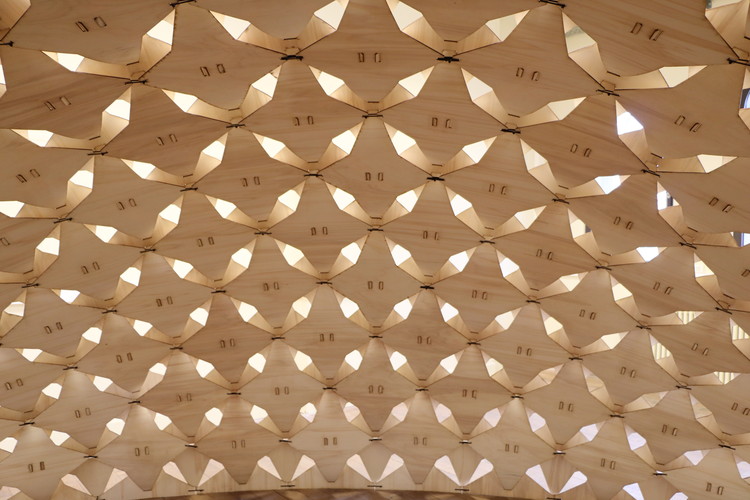

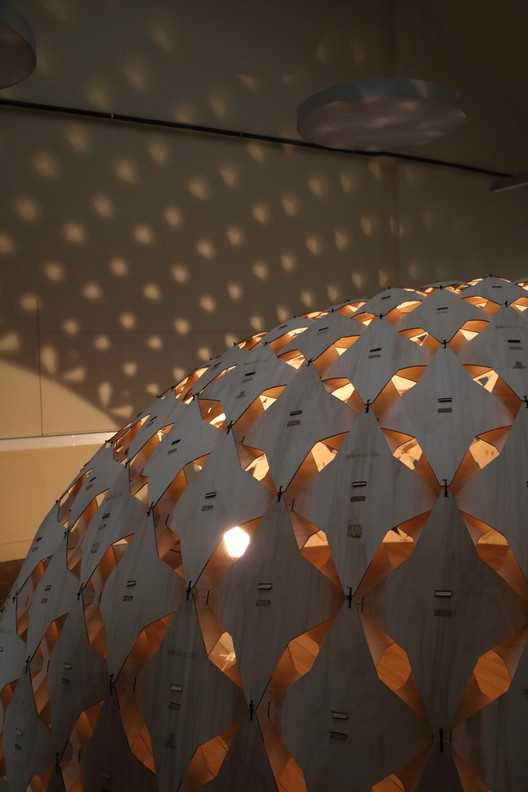

Thin plywood panels are chosen as material and 2D CNC-techniques (laser-cutting and milling) as form process. An investigation into the characteristics and physical behavior of the material was determining for the design since this bottom-up design process starts from the possibilities that lie within the material itself. Departing from the smallest element, the consequences and possibilities were investigated for an ascending hierarchy of scales. The design was directed by a continuous exchange of information between physical scale models, full-scale prototypes and the digital model.

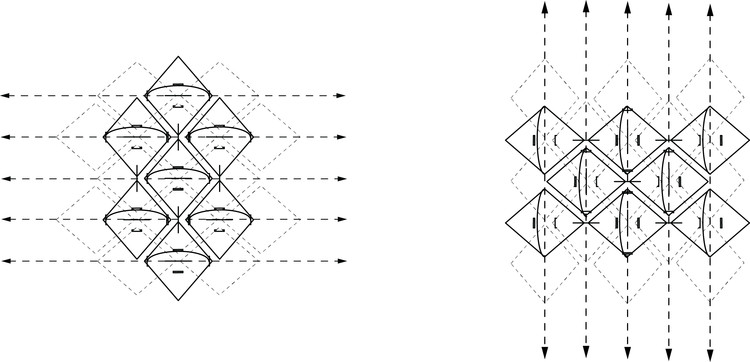

Applying a bottom-up design approach, we did succeed to investigate the innovative structural principle of active bending. Active bending refers to systemized elastic deformation of a certain material, as a form-giving and self-stabilizing strategy for static structures. Handling this bottom-up approach, it was possible to build a pavilion demonstrating this innovative structural principle in a short timespan, using only limited resources. As a consequence of the bottom up design approach, we designed a parametric system rather than a single pavilion. By applying the same assembly system to the designed modules with varying dimensions, different surfaces can be generated.

The objective was to build a structurally challenging pavilion that is digitally fabricated, in a limited time span and using only limited resources. This makes the pavilion accessible for everyone with access to a fablab, since the pavilion does not rely on complicated digital fabrication techniques. Applying a bottom-up approach to the structural design with rapid prototyping would be the most effective way to achieve this.

Specific targets were being put forward for the design of the pavilion itself. First of all, the amount of resources necessary to assemble and construct the overall pavilion should be as limited as possible. This decreases the total cost and creates an affordable pavilion. Also, the pavilion should be constructable by hand and easy disassembly should be possible. Only materials and fabrication techniques that are widely available should be used, making the assembly of this pavilion accessible to a large group of people.

This master’s dissertation contains a meticulously plotted overview of the different steps that we undertook during the bottom-up design process, following our entire workflow. Departing from the smallest element, the consequences and possibilities are investigated for an ascending hierarchy of scales, evolving from a flat surface to a double curved pavilion. The design is directed by a continuous exchange of information between full-scale wooden tests, paper prototypes and the digital model.

Only two types of connections were used in the pavilion: sliding joints and tie straps.

The sliding joints are a straightforward and elegant solution to connect the panels on the inside of the pavilion to those located on the outside (and the other way around). Since the panels are actively bent, the resilience force in the panels plugs them into the sliding joints. Therefore these joints can be very simple, no attached parts such as nails or screws are needed.

Tie straps are used to keep the panels in their bended position. Tie straps enable a fast and easy assembly, but they also serve as an important control mechanism. During construction, the more panels that are assembled, the higher the pavilion rises and the closer it gets to its final shape. Therefore it was necessary to have a connection that can be gradually tightened during construction. Tie straps, therefore, provided the ideal solution. All panels can be bent just as far as needed and the straps can be tightened further as the pavilion rises.

Lead Architects: Thibaut Van Dousselaere & Silke Van Geeteruyen

Team: Willem Bekers, Sebastiaan Leenknegt, Ruben Verstraeten, Arthur De Roover (University of Ghent, Department of Architecture and Urban Planning ), Jan Belis (Department of Structural Engineering), Stijn De Mil (Fablab Factory)

Location: Ghent, Belgium

Year: 2017

Area: 20 m2

Photography: Jeroen Christiaen & Saskia De Mol